Large roof areas cause high rainwater charges each year.

The roofs of production and manufacturing halls in particular represent a not inconsiderable cost factor for rainwater disposal in industrial and commercial operations.

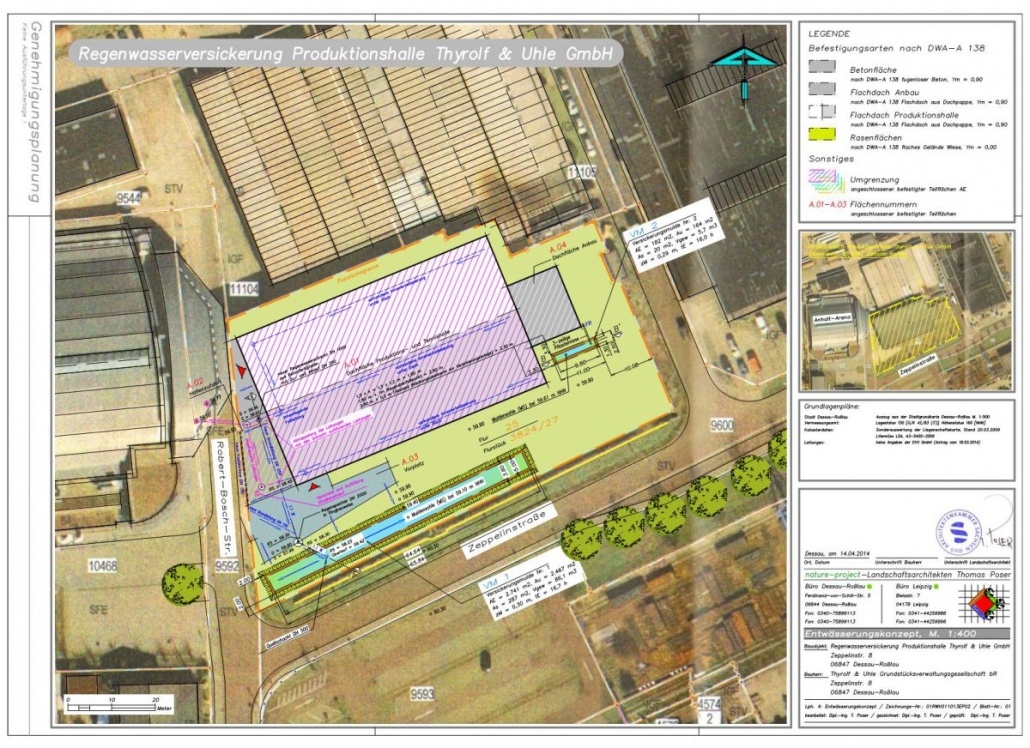

This was also the case with our project – a production hall at Thyrolf & Uhle GmbH in Dessau-Roßlau.

With a roof area of 2,342 m² and a record-breaking rainwater fee from the local disposal company, the metal processing company had to shoulder annual rainwater fees of around EUR 2,700 for this one production hall.

After recording and checking the property’s internal underground pipeline network and extrapolating it to a fee period of 10 years, which made the management aware of an increase in fees of around EUR 27,000, the course was set in the direction of decentralized rainwater management on their own property.

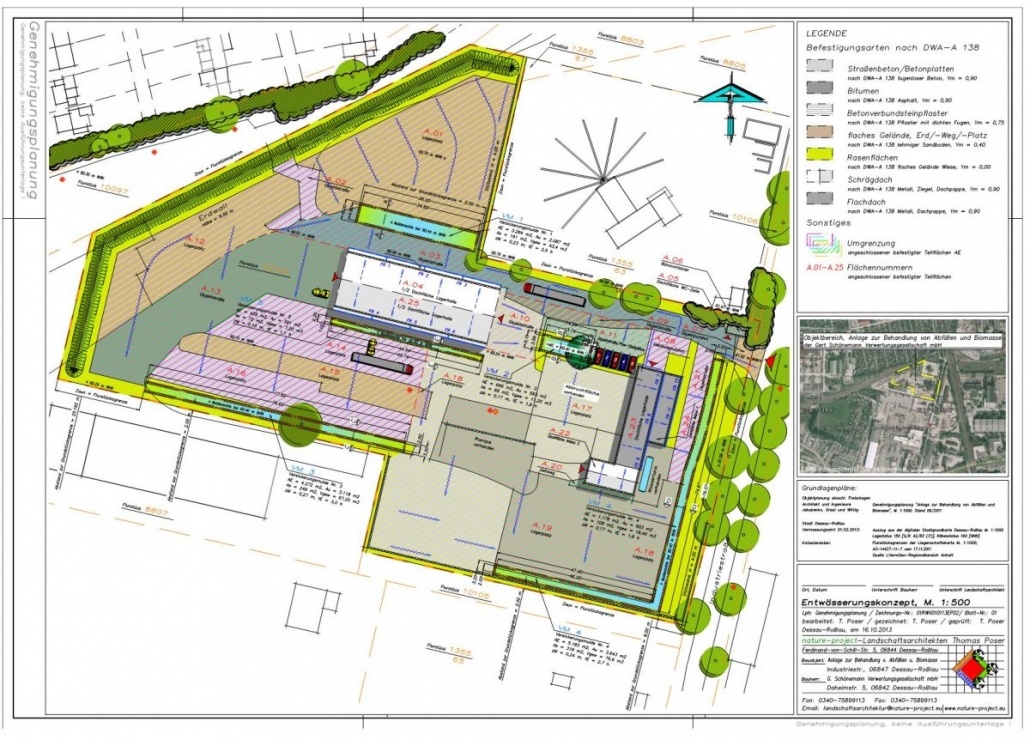

Drainage concept

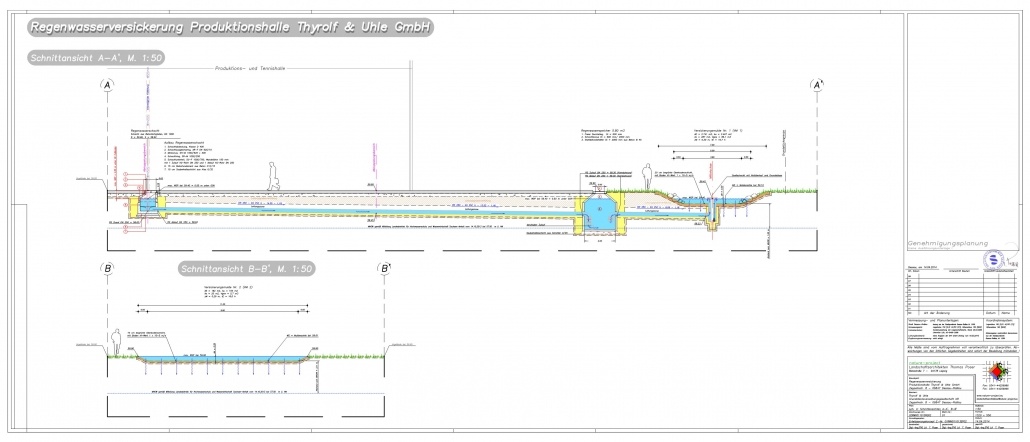

Sectional views

Using the principle of communicating pipes, it was also possible to use the property’s own underground pipe network to feed the lawn troughs with rainwater, so that cost-intensive civil engineering measures were not necessary and the most cost-effective infiltration variant was used.

It was worth it!

Further (hall) decoupling measures are currently being planned.

Rainwater management – decoupled from the sewer and the cost factor "rainwater" switched off

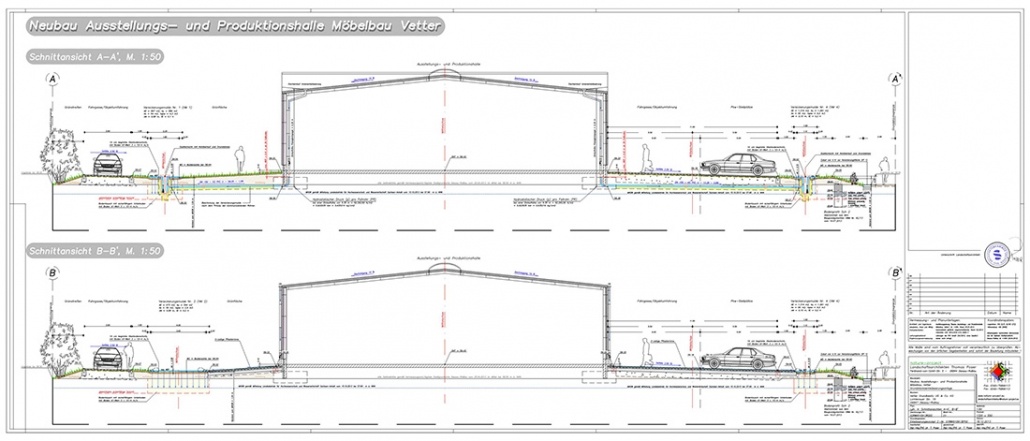

We received these and more answers from the responsible authorities and the municipal utility company when we came up with our idea of rainwater management for the new construction of a production hall, including of the outdoor facilities (in the industrial area Mitte) in Dessau-Roßlau presented to the licensing authority.

Especially the last statement (question), which every economically active company could have answered immediately in order to save costs, in our case not inconsiderable rainwater fees, made us look for new ways for the rainwater to solve the drainage problem.

The exemption of our client from the annual discharge fees and the periodic price increases of the wastewater company was very important to us.

After all, the rainwater charges projected over the medium term were around EUR 15,000.

An amount that must first be earned on the free market. And that only for the drainage of the valuable protected asset (rain) water.

Now that it had been explained to us in detail how not to do it, economic solutions had to be found in order to overcome the high groundwater level and achieve the seepage distance of one meter required by the DWA-A 1381 worksheet.

Because this (seepage passage of one meter) lay between us and the long-awaited water law permit for internal seepage, and thus the lifting of the cost-intensive compulsory use of the public sewage system (rainwater sewer).

As a result of the cost calculations, the elevation (filling) of the area in the area of the infiltration systems emerged as an economic partial solution in order to achieve the required distance of one meter from the groundwater level.

The required earth mass could be made available from the excavation areas of the production hall and the traffic areas.

Positive side effect:

The costs for soil disposal and excavation work have been significantly reduced.

Due to the favorable soil permeability (kf value), lawn troughs were planned as the most cost-effective system type for infiltration. The water is supplied above the ground from the outside downpipes of the production hall via open paving gutters or directly via the transverse slope of the traffic systems to the troughs in the lawn.

The connection of the internal drainage of the building to the troughs was more problematic, as the ground pipes landed below the troughs if they were laid in accordance with the norms at a depth of frost (ie pipe apex 0.8 m below the terrain + height loss due to the performance gradient).

The new factual question was now “How do you get the rainwater up without technical aids?”

The technical solution to this is as simple as it is old.

According to the principle of communicating tubes.

In vessels that are open at the top but connected at the bottom, a homogeneous liquid is at the same level because the force of gravity and the air pressure are constant (hydrostatic paradox).

This is how the ancient Romans built their aqueducts.

Due to the hydrostatic pressure resulting from the roof height, it is now possible

to feed the lawn troughs with rainwater via the underground pipes below.

The water is distributed in the troughs in the turf using specially designed spring pots made from KG molded pieces.

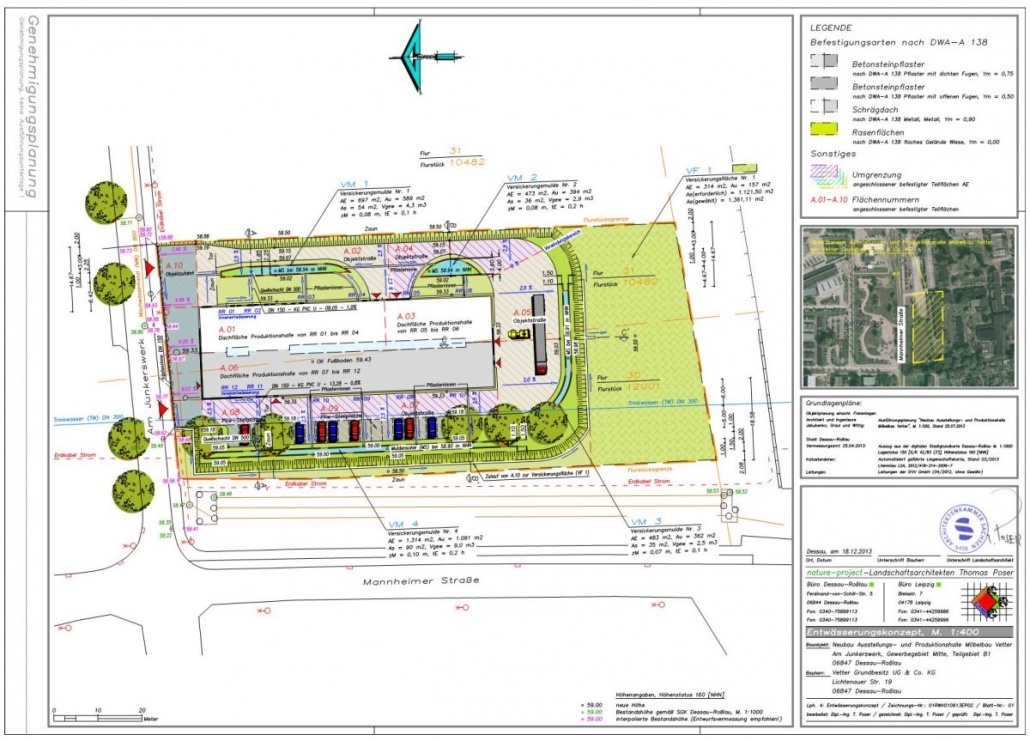

Drainage concept

Sectional views

Conclusion:

It pays to think, first check the feasibility of rainwater infiltration and then build.

The result of the cost calculations made it clear that in addition to saving rainwater charges (around EUR 3,000 per year), the construction costs can also be reduced compared to a conventional drainage solution (sewer connection) through a sophisticated rainwater management system.

In the present project, this is explained by the elimination of many cost-intensive underground drainage facilities (underground pipes and manhole structures) and the favorable soil permeability at the site, which made it possible to create more cost-effective infiltration troughs here.

1.) Worksheet DWA-A 138 “Planning, construction and operation of systems for infiltration of rainwater” is the relevant set of rules for the planning and approval of systems for infiltration of rainwater.

Rainwater management – economically planned and saved high rainwater charges

With new investments and the expansion of industrially operated plants, approval according to the Federal Immission Control Act, better known as BIm SchG, is usually required.

What is less well known is that proof of proper disposal of the rainwater produced must also be provided for the existing systems

.

Our practical experience shows that there is generally no water law permit for existing properties, as this (water law permit) was not required at the time of initial commissioning.

The fact is:

The protection of the existing property is revoked under water law by the new approval procedure. Evidence of the disposal of the accumulating rainwater in accordance with the permit must be provided for all areas (whether old or newly planned).

This is how it came about for a Dessau waste disposal company to expand its demolition business on the site of a disused industrial area.

In the course of the BIm Sch procedure, the proper disposal of the accumulating rainwater had to be proven for the entire company premises, either through the connection to the public sewage network or the decentralized infiltration on the own property.

Mit Bezug auf den hohen Versiegelungsgrad der Industriefläche (Au = 10.605 m² undurchlässige Fläche) und die daraus resultierenden Einleitgebühren von rund 13.000 EUR/Jahr (mittelfristig rund 65.000 EUR) fiel der Geschäftsführung die Entscheidung nicht schwer.

It favored the internal infiltration of rainwater.

In order not to destroy the existing surface structure of traffic, storage and open space areas, grass troughs were planned at the low points and in the side areas of the paved surfaces.

They represent the most cost-effective infiltration option.

Drainage concept